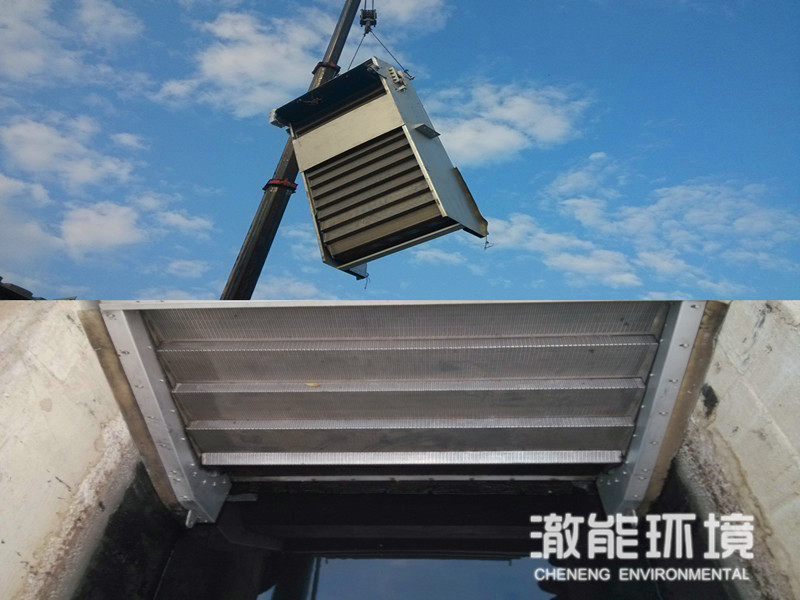

WJG mesh type ladder grille decontamination machine

product description

WJG mesh type ladder grille decontamination machine is a kind of fine grille. It has good adaptability and removal effect for fine particles and fibrous garbage in sewage. It solves the problems of entanglement and jamming of the grille.

Scope of application

It is generally used in the second sewage block behind the coarse grid of waterworks or industrial sewage treatment plants to remove smaller suspended particles.

Outstanding advantages

1. The stepped perforated mesh plate design is adopted, with a large filtering area, easy to trap dirt, and high filtering efficiency; especially for fibrous garbage, it has strong adaptability;

2. The box-plate structure is adopted, the whole structure is firm, the symmetry is high, the operation is stable, and the installation is simple;

3. The sewage environment is fully considered in the structural design, and the heavy-duty drag chain is used as the main body of the filter screen; there is no underwater bearing structure, which greatly reduces the probability of underwater failures and makes the operation more reliable;

4. The use of high-efficiency rotating brush and backwashing dual devices to help remove dirt and ensure effective regeneration of the filter surface;

5. The upper part adopts front and rear closed structure, which is directly connected with the slag conveyor to improve the use environment;

6. Fully automatic operation control can be carried out according to the water level difference or timing to achieve the best energy saving effect;

working principle

WJG mesh type ladder grille decontamination machine is mainly composed of frame, perforated mesh plate chain, transmission mechanism and so on. Among them, the porous mesh plate is installed on the heavy-duty traction chain to form a stepped filter surface. After the sewage passes through the filter surface, the garbage larger than the mesh diameter will be trapped on the filter surface and lifted out of the water surface with the movement of the mesh plate. It is discharged on the filter surface to achieve cleaning.

|

格栅宽度 B(mm)

|

600~3000

|

|

建议格栅井宽 B1(mm)

|

B+100

|

|

有效过滤面宽度(网板宽度)B2(mm)

|

B-150

|

|

建议格栅井深度 H(m)

|

1.5~10

|

|

安装角度 (°)

|

60~75

|

|

常用网孔直径 (mm)

|

3,5,6, 8, 10

|

|

网板运行速度 (m/min)

|

~3.8

|

|

主传动功率(kW)

|

0.75~3.0

|

|

清洗刷功率(kW)

|

0.37~0.75

|

|

冲洗水压力(MPa)

|

≥0.3

|

|

设计****水位差(m)

|

1.0

|

|

单位过水流量(参考)(m3/m2.h)*

(水流速度0.8m/s,有效水深1m)

|

孔径:≤3

|

700

|

|

孔径:4~6

|

900

|

|

孔径:7~10

|

1200

|

*:1)工艺设计计算过程如下:

过水流量(m3/h)=单位过水流量(m3/m2.h)×有效过水面积(m2)

有效过水面积(m2)=有效水深(m)×有效过滤面宽度(m)

有效水深(m)(设计井内水流速度在0.8m/s)=栅前水深(m)-水头损失(m)

水头损失参考值见下表:

|

不同孔径格栅水头损失参考值(m)

(水流速度0.8m/s)

|

孔径:≤3mm

|

0.6

|

|

孔径:4~6mm

|

0.5

|

|

孔径:7~10mm

|

0.4

|

2)设计流速等工艺设计参数变化时,请与澈能公司的工程师联系,帮助设计选型。

|